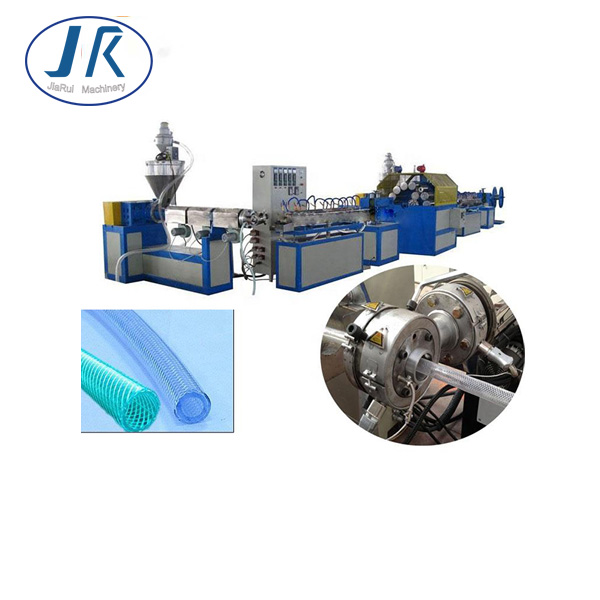

PVC Braided Hose Extrusion Line

This production line is used to produce PVC fiber reinforced garden hoses with a diameter of 8mm to 50mm. The hose wall is made of PVC material. There is fiber in the middle of the hose. According to requirements, we can produce braided hoses of different colors, three-layer braided hoses, and five-layer braided hoses.

The extruder uses a single screw with excellent plasticizing performance. The tractor has 2 claws and its speed is controlled by an ABB frequency converter. Appropriately, the fiber layer can be crochet and knitted

The pvc resin powder is mixed with a plasticizer to form pvc particles.

We melted the pvc particles. The melted liquid is then extruded by the first extruder through mould to form the inner layer of the pvc hose

We use water to cool pvc hose inner layer and it is conveyed to the woven machine by the first tractor.

The polyester yarn is then woven around the inner layer of the pvc hose. Then dry the water on the hose by oven. After then pvc particles are then heated, melted again, and extruded by the second extruder through a mould onto the fibrous layer, thus forming the outer layer of the pvc hose.

We also need to cool the pvc hose as it’s surface is too hot now. So it is conveyed to the cooling frame by the second tractor.

Selection table

| Model | L/D Ratio | Screw | Material | Screw diameter | Output | Total Power | Production Scale |

| SJ45/30 | 30:1 | Separative style | 38crmnal | 45mm | 60kg/hr | 35kw | Φ6-16mm |

| SJ65/30 | 30:1 | Separative style | 38crmnal | 65mm | 120kg/hr | 50kw | Φ16-50mm |