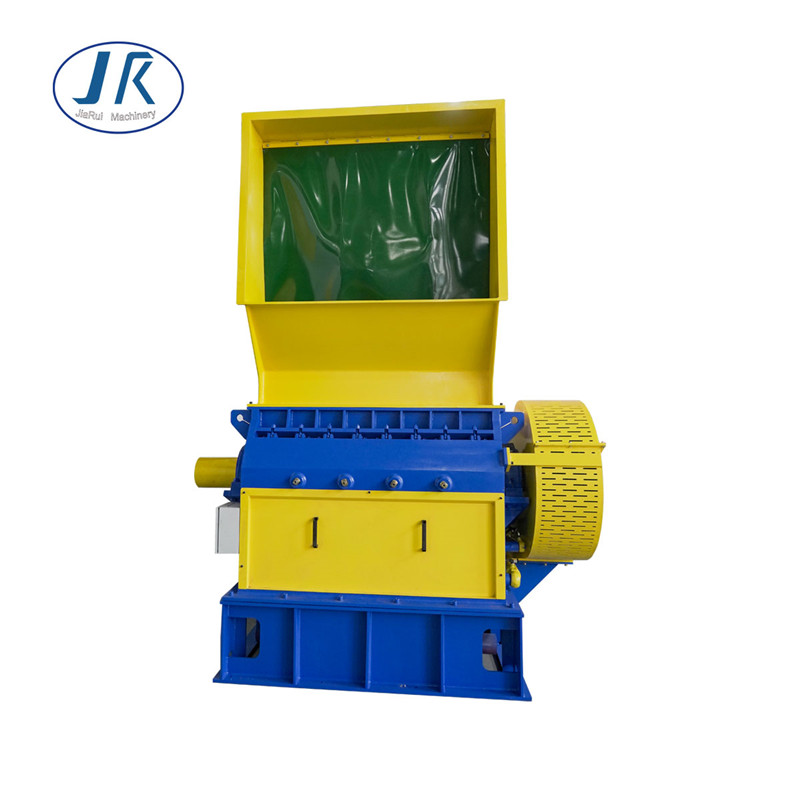

Efficient and Durable Door Plate Crusher for Home and Business Use

Introducing Suzhou Jiarui Machinery Co., Ltd.'s innovative Door Plate Crusher, designed to efficiently crush and recycle door plates and frames. Our cutting-edge crusher is built with advanced technology and precision engineering, making it a reliable and essential tool for door plate recycling businesses, The Door Plate Crusher is easily operable and requires minimal maintenance, offering a cost-effective and time-saving solution for door plate processing. It is capable of crushing door plates of various sizes and materials, including metal and plastic, and can handle a high volume of door plates in a short amount of time, Suzhou Jiarui Machinery Co., Ltd. is committed to providing high-quality and durable equipment for the recycling industry, and the Door Plate Crusher is no exception. Our product is designed to meet the demands of modern door plate recycling operations, offering a sustainable and efficient solution for door plate waste management, Choose Suzhou Jiarui Machinery Co., Ltd.'s Door Plate Crusher for reliable performance and exceptional results in door plate recycling

Send Email

Send Email whatsapp

whatsapp