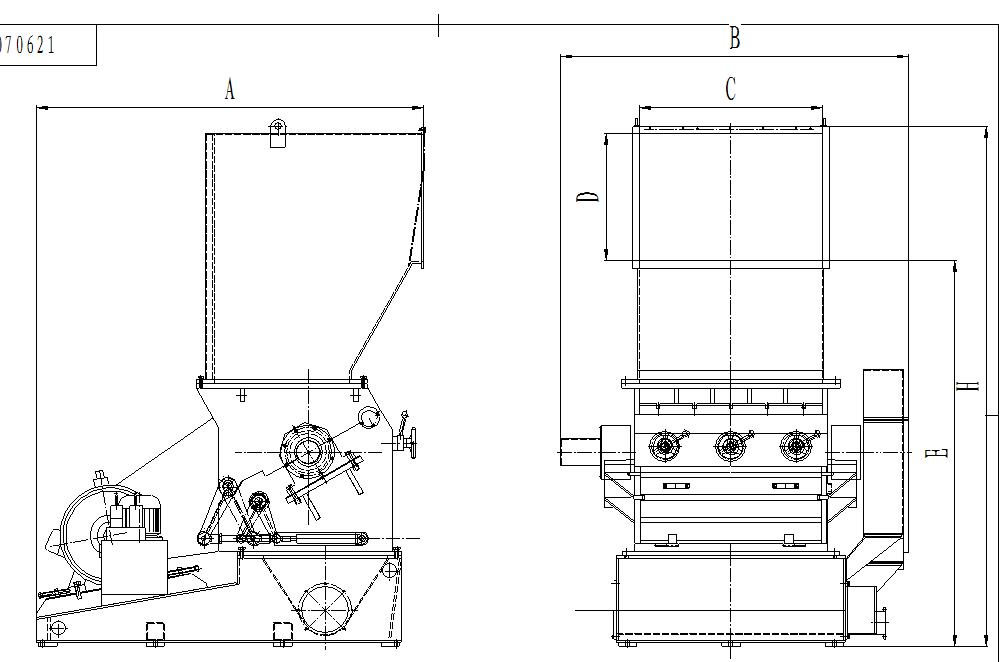

PC Heavy Duty Crusher

Model & Parameters

|

Model |

PC52100 |

PC52120 |

PC66120 |

PC66160 |

| A(mm) |

2119 |

2070 |

2435 |

2360 |

| B(mm) |

2035 |

2251 |

2304 |

2815 |

| C(mm) |

1034 |

1234 |

1234 |

1634 |

| D(mm) |

708 |

708 |

1080 |

1080 |

| E(mm) |

2236 |

2241 |

3214 |

3214 |

| H(mm) |

2984 |

2945 |

4339 |

4344 |

| Rotor Diameter(mm) |

φ520 |

φ520 |

Ф660 |

φ660 |

| Rotor Speed(r/min) |

462 |

462 |

462 |

415 |

| Screen Mesh Size (mm) |

φ12 |

φ12 |

φ12 |

φ12 |

| Rotor Blades(PCS) |

5*2 |

5*2 |

5*2 |

5*2 |

| Stator Blades(PCS) |

2+2/3+3 |

2+2/3+3 |

2+2/3+3 |

4+4/6+6 |

| Main Motor Power(KW) |

55 |

75 |

90 |

132 |

| Weight(KG) |

4200 |

5300 |

7650 |

9720 |

Write your message here and send it to us