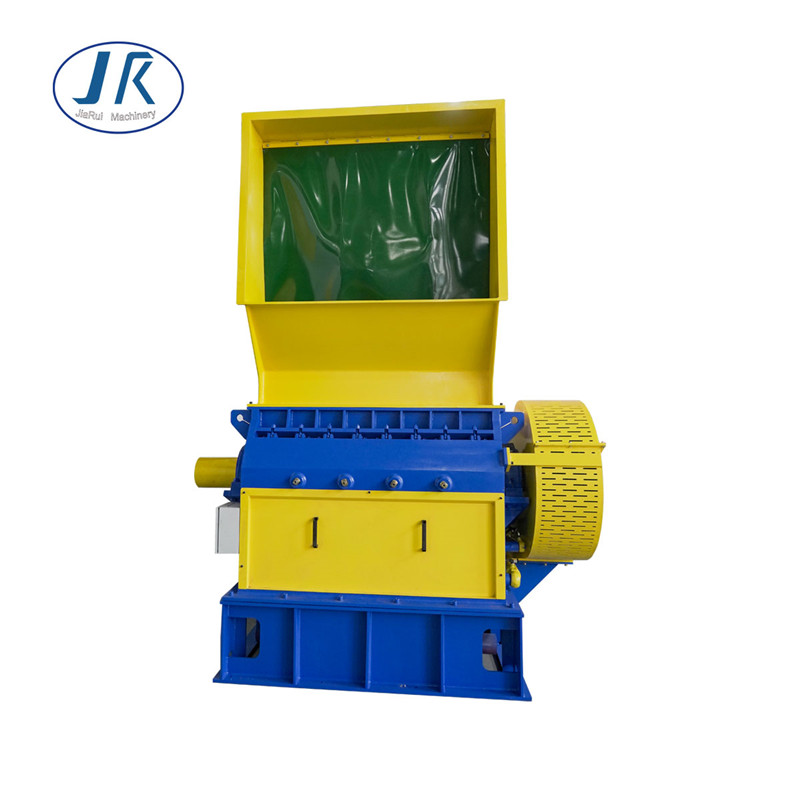

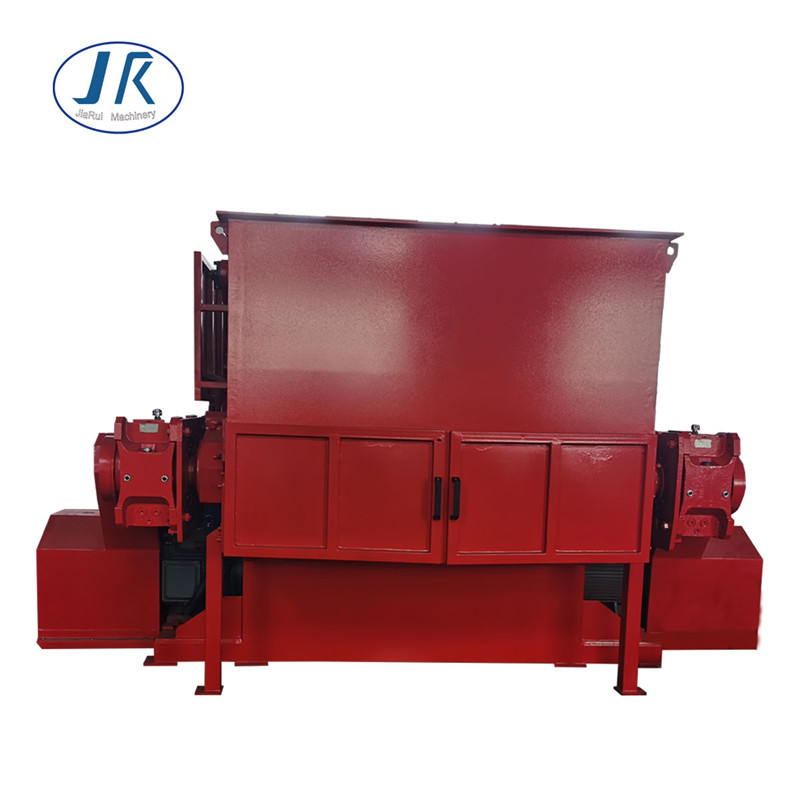

Durable Tire Crusher: Efficient and Reliable Equipment

Introducing the Tire Crusher from Suzhou Jiarui Machinery Co., Ltd., a high-quality and efficient solution for recycling and processing scrap tires, Our Tire Crusher is designed to shred and crush used tires into small, uniform pieces, making them easier to transport and recycle. With a powerful motor and durable blades, this machine can quickly and effectively reduce the volume of waste tires, allowing for more efficient storage and disposal, The Tire Crusher is also equipped with advanced safety features to protect operators and minimize the risk of accidents during the crushing process. Additionally, it is designed with easy-to-use controls, making it user-friendly and accessible for operators of all skill levels, At Suzhou Jiarui Machinery Co., Ltd., we are committed to providing durable and reliable machinery for the recycling industry, and our Tire Crusher is no exception. With its superior performance and quality construction, it is the perfect solution for businesses looking to streamline their tire recycling operations. Contact us today to learn more about our Tire Crusher and how it can benefit your business

Send Email

Send Email whatsapp

whatsapp