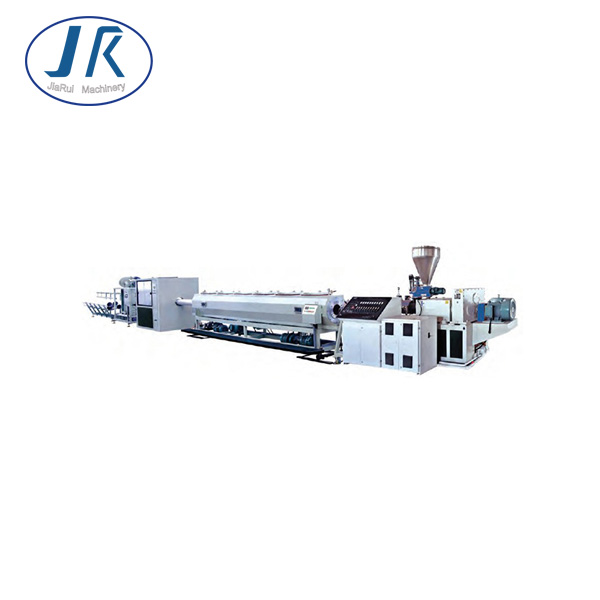

PVC pipe production line

The tank body of vacuum calibration and cooling units adopt stainless 304# steel, multi-sections vacuum system ensures the stable sizing and cooling for pipes; Special cooling system improves the cooling efficiency; Auto water temperature control system make the machine more intelligent.

For different pipe size, the haul-off machine will adopt two caterpillars, three caterpillars, four caterpillars, six caterpillars are designed for different requirements. Pedrail clamping uses mechanical and pneumatic combining system, which is more reliable in performance

Cutting system adopts no-dust cutter or planetary cutting means; There is dust-collecting system ensures clean working environment.

This production line adopts special screw and mold design, which makes the material easy to form, uniform plasticization, fast production speed, stable operation and convenient control operation.

In order to release the capacity of extruder more effectively, especially when facing small diameter PVC pipe, it is necessary to output multiple pipes at one time.

Therefore, we have added PVC double outlet pipe production line and four outlet pipe production line.

This Double Pvc Pipe Line is widely used for producing pvc water supply pipe,drainage pipe and high voltage cable protection pipe.With PVC pipe mold ,it could also produce PVC pipe.it is consist of SJSZ series extruder ,mold,vacuum tank,spraying cooling tank, haul-off,cutting machine,stacker, and can produce PVC pipe from mixed powder directly.

This double pipe extrusion line uses special designed screw and mould ,which makes it easy forming ,even plasticization,high capacity,stable running and easy operation.

Selection table

|

Extruder model |

SJSZ51/105 |

SZSJ65/132 |

SJSZ80/156 |

SJSZ92/188 |

|

Max.Diameter(mm) |

75 |

200 |

315 |

630 |

|

Motor power(kw) |

18.5 |

37 |

55 |

90 |

|

Drawing machine(m/min) |

0.5-10 |

0.5-8 |

0.5-6 |

0.5-4 |

|

Total length (m) |

20 |

25 |

28 |

32 |

|

Output (Kg/H ) |

80-120 |

180-250 |

280-350 |

500-600 |