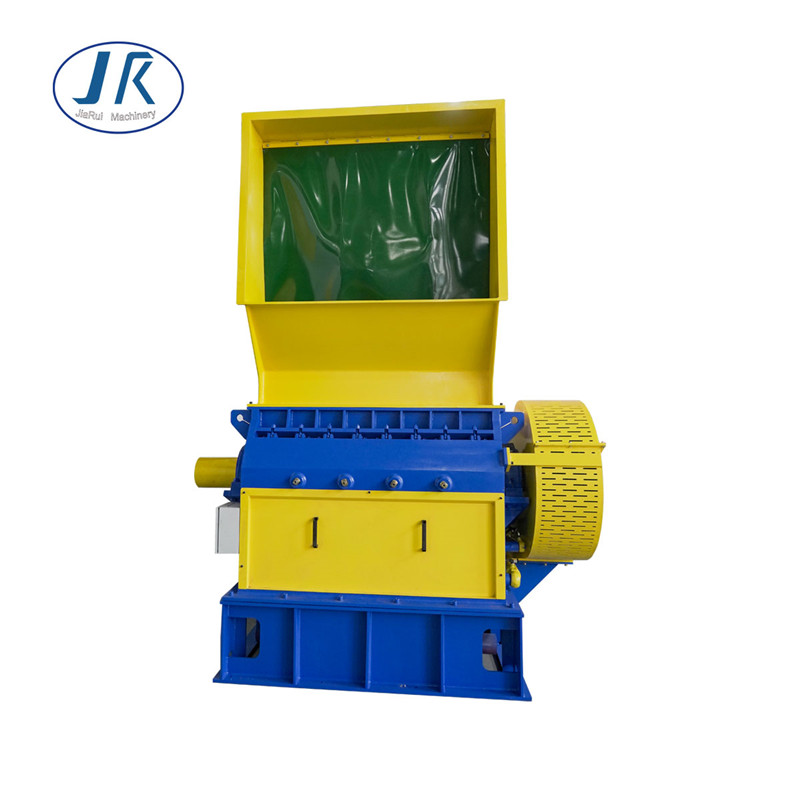

Maximize Your Efficiency with Profile Crushers - Get Yours Now!

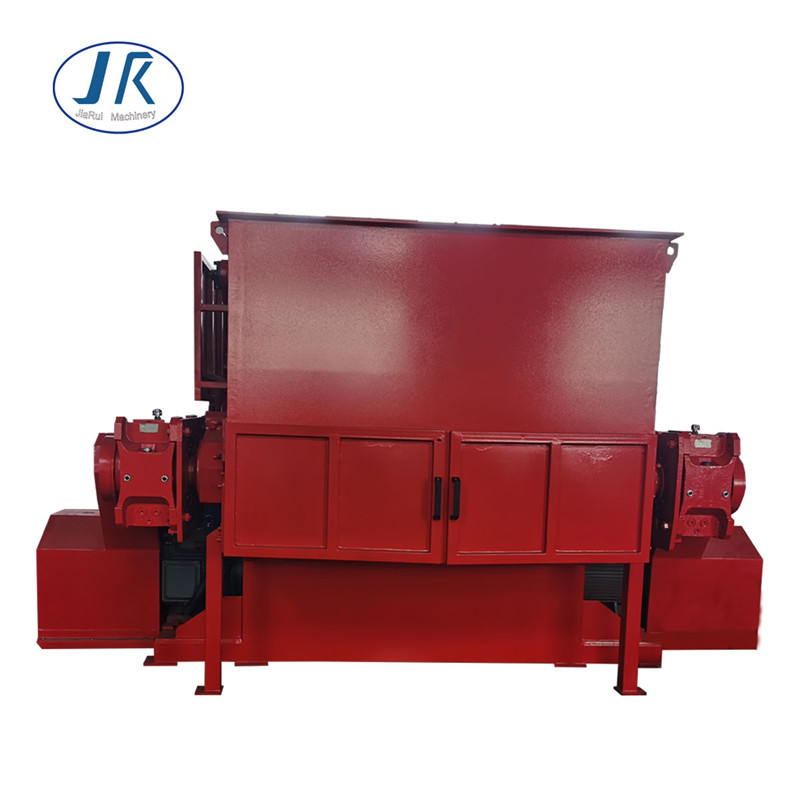

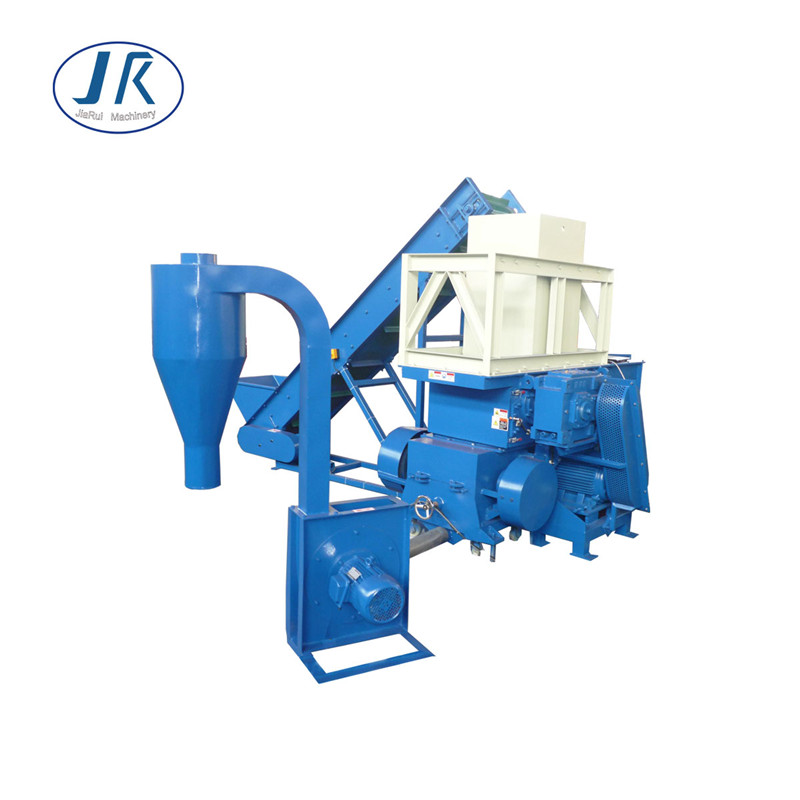

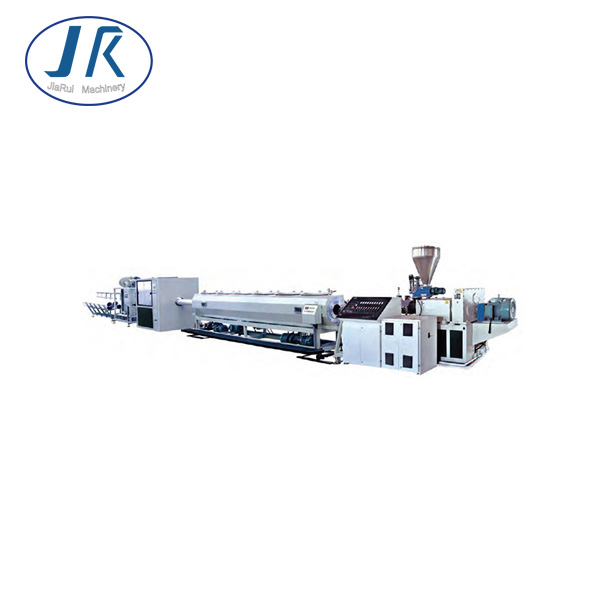

Introducing the Profile Crusher, a high-performance and precision-engineered machine designed and manufactured by Suzhou Jiarui Machinery Co., Ltd. This innovative machinery is specifically developed for the efficient crushing of various profiles and materials, including plastic, PVC, aluminum, and other non-ferrous metals, The Profile Crusher is equipped with advanced technology and intelligent control systems, ensuring the accuracy and consistency of the crushing process. It features a robust and durable structure, making it suitable for continuous and heavy-duty operations in industrial settings. With its high crushing capacity and adjustable speed control, this machine offers versatility and flexibility for different profile shapes and sizes, In addition, the Profile Crusher is designed with safety features and user-friendly interfaces, providing ease of operation and maintenance. Its efficient performance and reliable quality make it an ideal choice for manufacturers and businesses in the recycling, material handling, and construction industries, Trust Suzhou Jiarui Machinery Co., Ltd. for a superior Profile Crusher that meets your production needs and delivers exceptional results

Send Email

Send Email whatsapp

whatsapp