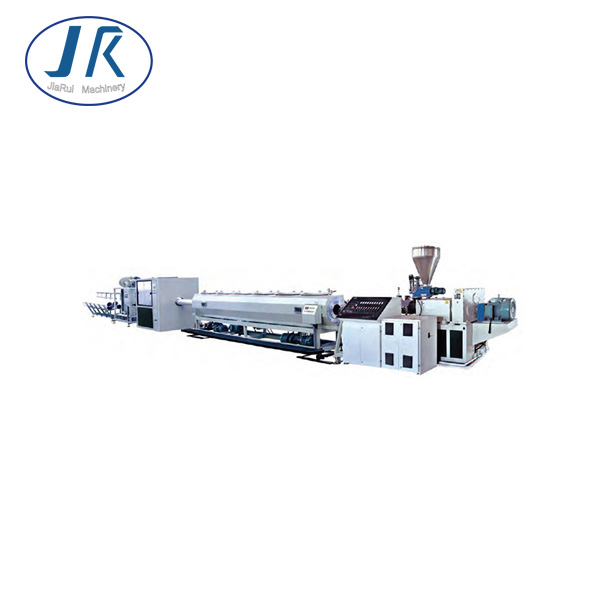

High Quality Shower Pipe Production Machine for Efficient Manufacturing

Introducing our state-of-the-art Shower Pipe Production Machine, manufactured by Suzhou Jiarui Machinery Co., Ltd. Our machine is designed to meet the high demands of the plumbing industry by producing high-quality shower pipes with precision and efficiency, With advanced technology and professional engineering, our machine is capable of automatic pipe cutting, bending, welding, and shaping, ensuring consistent and accurate production with minimal human intervention. The machine is also equipped with quality inspection systems to guarantee the integrity of the pipes, Our Shower Pipe Production Machine is built with a sturdy and durable framework, ensuring reliable and long-lasting performance. It is also user-friendly, with intuitive controls and easy maintenance features, making it an ideal choice for both large-scale production facilities and small workshops, At Suzhou Jiarui Machinery Co., Ltd., we are committed to providing top-notch machinery solutions to meet the evolving needs of the industry. With our Shower Pipe Production Machine, you can elevate your production capabilities and deliver premium quality shower pipes to your customers. Contact us today to learn more about our advanced production machines

Send Email

Send Email whatsapp

whatsapp