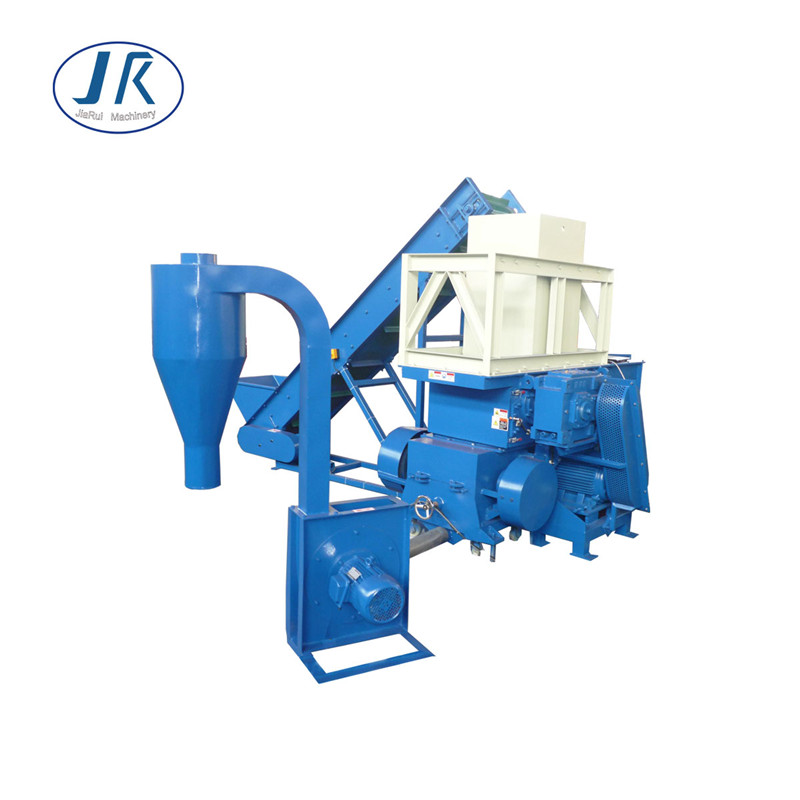

High-Quality Plastic Granules Twin Screw Extruder for Efficient Production

Suzhou Jiarui Machinery Co., Ltd. is proud to introduce our high-quality Plastic Granules Twin Screw Extruder. This extruder is designed for efficient and precise processing of plastic granules, providing a reliable and consistent production output, Our Twin Screw Extruder features a co-rotating, intermeshing design that ensures thorough mixing and excellent dispersion of materials. With its advanced screw and barrel configuration, it provides excellent wear resistance and long service life, The machine is equipped with state-of-the-art controls and advanced technology for smooth and efficient operations. It also offers easy maintenance and cleaning, making it an ideal choice for plastic processing industries, The Plastic Granules Twin Screw Extruder from Suzhou Jiarui Machinery Co., Ltd. is suitable for a wide range of applications including compounding, extrusion, recycling, and more. With our commitment to quality and innovation, our extruder delivers outstanding performance and productivity, meeting the demands of modern plastic processing operations, Contact us today to learn more about our Plastic Granules Twin Screw Extruder and how it can benefit your production processes

Send Email

Send Email whatsapp

whatsapp