PE multi-layer pipe extrusion line can make 2, 3, 4, 5 layers of pipes by multiple main machine compound extrusion.

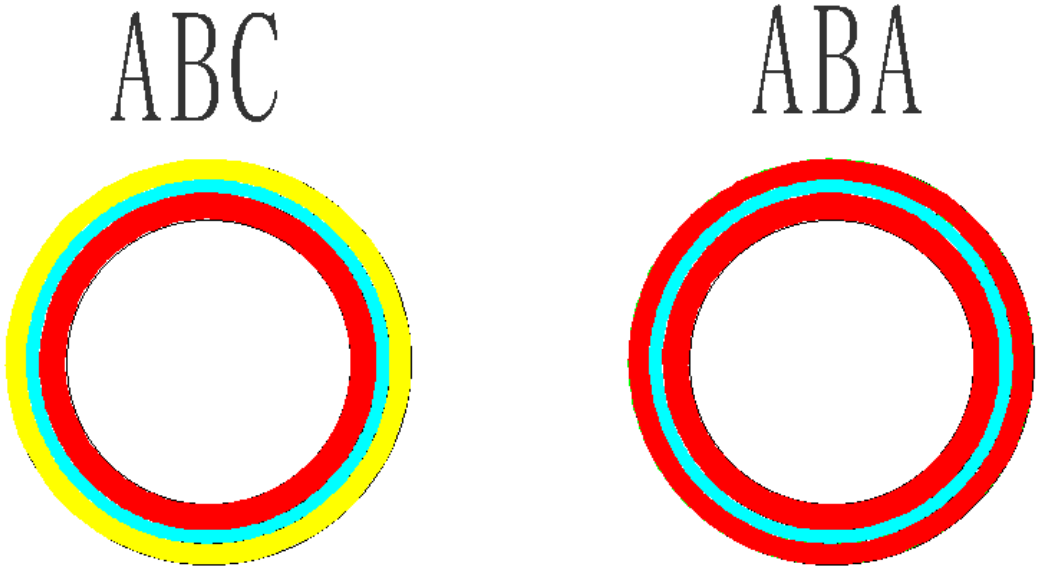

For the production of multi-layer pipe, the more layers, the more materials, the more difficult it is to produce. Different layers will also have different differences. For three layer pipes, there are two types. ABA and ABC require two and three single screw extruders to co extrude. For equipment, ABC is much more difficult and equipment cost is much higher than ABA.

PE multi-layer pipe is mainly used for municipal water supply and drainage, agricultural irrigation, etc. through different composite materials and layers, it can reduce cost, increase physical strength and increase antioxidant.

For the common composite pipe production line, the biggest feature of high efficiency composite pipe production line is high efficiency and energy saving. Under the premise of the same extrusion capacity, the screw is smaller, the energy efficiency is lower, and the site and labor are more saved.

Compared with the same period of the same period, the output of 60/30 ordinary single screw extruder is only 100kg per hour, while the extrusion capacity of high-efficiency 60/38 high-efficiency single screw extruder is over 350 kg per hour, which is equivalent to the general efficiency of three and a half. The energy consumption is only 2.8 times of that of ordinary extruder, and the energy consumption ratio is increased by nearly 25%. The energy consumption is greatly reduced, the product performance is optimized, and the production space is greatly reduced.

PE multi-layer pipe production line can produce pipe diameter of 20-1200mm, and the specifications of high-efficiency single screw extruder are mainly 50/38, 60/38, 75/38, 90/38120/38150/38. the extrusion capacity is 200-1200kg/h, and the extruder motor is 55kw-550kw, so as to meet the needs of customers with different pipe diameters.

Post time: Oct-29-2020